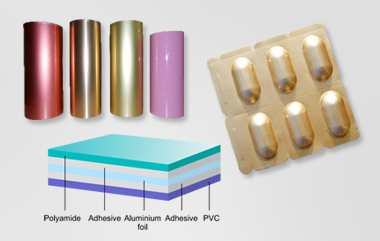

Cold Form Blister Foil (Alu-Alu Foil)

Features:

- Impermeable barrier to moisture, light, oxygen and other gases

- Versatility with selection of stiffness, print and color options

- Economical, faster deliveries and flexible quantity

Key benefits:

- Optimal protection extends product shelf life

- Smallest cavity design results in low material usage

- Unsurpassed quality, consistent performance, maximizes production reliability

Anti-counterfeit solutions:

Alu-Alu foil can be produce with reverse printing or sandwich printing which acts as an anti-counterfeit for your product.

- OPA Film (Nylon)

- Reverse Printing on OPA Film

- Aluminum Foil

- PVC Film

can be produced with various colors like Golden, Red, Pink etc. Any customized color can be developed & standardized / reserved based on the requirements.

Cold Form Blister Foil (Alu-Alu Foil) features an impermeable barrier to moisture, light, oxygen, and other gases which provide extended shelf life and long term de-lamination resistance.

| Standard Specifications of ALU-ALU FOIL | ||

| OPA Film (Nylon) | 25 µ | 25 µ |

| Aluminum Foil | 50 µ | 45 µ |

| PVC Film | 60 µ | 60 µ |

Alu-Alu Blister foil is an excellent multi layered structure designed for high sensitive range of pharmaceutical and generic medicines which are highly hygroscopic or light and heat sensitive.

| Three Layer | |

| OPA Film (Nylon) | 25 µ |

| Aluminum Foil | 45 µ or 50 µ or 60 µ |

| PVC Film | 60 µ or 100 µ |

Alu-Alu foil comply with the regulatory requirements as well norms of pharmaceutical industry.

| Four Layer | ||

| PVC Film | 60 µ | |

| OPA Film (Nylon) | 25 µ | |

| Aluminum Foil | 45 µ or 50 µ or 60 µ | |

| PVC Film | 60 µ | |

Other specifications are available on request

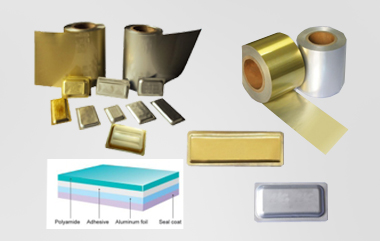

Tropical Blister Foil

Features:

- Impermeable barrier to moisture, light, oxygen and other gases

- Versatility with a selection of stiffness, additional print surface and colors

- Economical and faster deliveries

Key benefits:

- Protective barrier enhancement of thermoformed blisters extends product shelf life

- Unsurpassed quality: consistent performance maximizes production reliability

- Temperature resistance

- Increased stiffness

Tropical Blister laminate layer is the ideal enhancement to conventional thermoformed blisters. It creates an impermeable barrier to moisture, light, oxygen and other gases, as well as being a protective barrier enhancement to extend product shelf life. The layer is added as a secondary base web, so has no direct product contact.

| Specifications of TROPICAL BLISTER FOIL | ||

| OPA Film (Nylon) | 25 µ | 25 µ |

| Aluminum Foil | 50 µ | 45 µ |

| PVC Film | 60 µ | 60 µ |

| Specifications of TROPICAL BLISTER FOIL | ||

| OPA Film (Nylon) | 25 µ | 25 µ |

| Aluminum Foil | 50 µ | 60 µ |

| HSL Coating | 6 to 8 gsm | 6 to 8 gsm |

Other specifications are available on request

Anti-counterfeit solutions:

TROPICAL BLISTER FOIL can be produce with reverse printing or sandwich printing which acts as an anti-counterfeit for your product.

- OPA Film (Nylon)

- Reverse Printing on OPA Film

- Aluminum Foil

- PVC Film

TROPICAL BLISTER FOIL can be produced with various colors like Golden, Red, Pink etc. Any customized color can be developed & standardized / reserved based on the requirements

Pharmaceutical Strip Foil

Features:

- Excellent battier to transmission of moisture, light, vapour & gases

- Non toxic, both aluminium foil & heat seal medium

- Excellent printability

- Eco-friendly, recyclable

The Pharmaceutical Strip Foil, soft aluminum foil laminated with low density polyethylene, manufactured using heat and press technology, meeting international quality standards provides perfect seal integrity.

Structure:

| Pharmaceutical Strip Foil | Print Primer |

| Aluminium Foil | |

| PE Film |

The raw materials used in constructing these structures and/or used for manufacturing these products are suitable for direct contact with food in conformance with the following directives.

| PET Film thickness | Foil thickness | Poly film thickness | Printing | Peel/Bond strength | Optional product |

| 12µ ± 5 % | 7/9/12µ ± 8 % | As specified by the customer ± 10 % | Up to 8 colours reverse printed on PET film | PET – Foil 200g/ 15 mm min. Foil – Sealant Poly 200g /15 mm min. | Can be supplied in pouch form. Type of pouch and its dimensions are as specified by the customer |

PET – FOIL – POLY Laminates

Features:

- Excellent barrier to transmission of moisture, light, vapour & gases

- Non toxic E

- Excellent printing quality

The Pharmaceutical Strip Foil, soft aluminum foil laminated with low density polyethylene, manufactured using heat and press technology, meeting international quality standards provides perfect seal integrity.

Structure:

| Pet – Foil – Poly Laminates | PET Film |

| Printing Ink | |

| Adhesive | |

| Aluminium Foils | |

| PE Film |

The raw materials used in constructing these structures and/or used for manufacturing these products are suitable for direct contact with food in conformance with the following directives.

| PET Film thickness | Foil thickness | Poly film thickness | Printing | Peel/Bond strength | Optional product |

| 12µ ± 5 % | 7/9/12µ ± 8 % | As specified by the customer ± 10 % | Up to 8 colours reverse printed on PET film | PET – Foil 200g/ 15 mm min. Foil – Sealant Poly 200g /15 mm min. | Can be supplied in pouch form. Type of pouch and its dimensions are as specified by the customer |

Pharmaceutical blister foil for multiple polymer substrates

Features:

- Excellent barrier to transmission of moisture, light, vapour & gases

- Non toxic, both aluminium foil & heat seal medium

- Excellent printability

- Eco-friendly, recyclable

The Pharmaceutical blister foils manufactured meeting the international quality standards provides seal integrity with specified polymer.

Structure:

| Pharmaceutical blister foil for multiple polymer substrates | Printer primer |

| Aluminium Foil | |

| Heat Seal Coating |

The raw materials used in constructing these structures and/or used for manufacturing these products are suitable for direct contact with food in conformance with the following directives.

| Foil Gauge | Heat Seal Coating weight | Specified Polymers for Heat Sealability | Heat resistance property of heat seal lacquer | Pin hole count per square meter | Optional in printed products |

| 20/25/30/40 µ Hard / Soft tempered with tolerance of ± 8 % | Standard 4-6 / 6-8 gsm |

PVC PVdC coated PVC PET | Up to 230® C | < 5 in 20 µ foil. Above 20 µ zero | Protective coating to increase scuff resistance to avoid blackening on polymer substrate side |