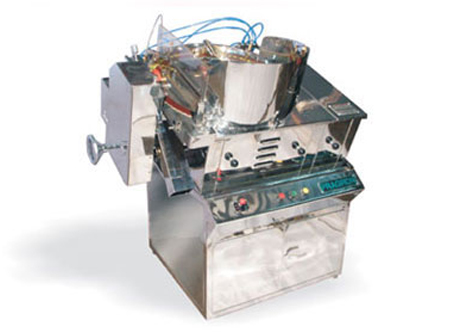

ROTARY SINGLE DISC PRODUCT COUNTER & BOTTLE FILLING MACHINE

Capsule / Tablet Counting and Filling ( Rigid Container , Plastic Bottle, Glass Bottle, Pouch etc.), Semi automatic model is suitable for Bulk counting and automatic models are ideal for small counts 20's, 50's,100's.... pack

Features:

Designed to precisely count and pack capsules and tablets of any size. More hygienic and easier to count and pack capsules / tablets, thus improving GMP standards. Special Dust Extractor to remove dust particles which ensures dust-free filling of tablets or capsules into the container. Heavy duty Gear-Box ensures smooth operation.

It is very simple to operate the machine which is controlled by a Push Button.

TABLET / CAPLET VISUAL INSPECTION MACHINE

- Compact Design

- No change part required

- High-speed visual inspection with high output

- Both coated and uncoated tablets & caplets of all sizes can be inspected

- Food grade endless PVC belt

- Magnifying lens provide for better viewing

- Complete tablet surface is inspected on both faces

- Angular guides provide on the edge of the conveyor make tablets to rotate 360 degree to Inspect the tablet edge

- Perforated vibratory plate for dust extraction provided

- Hopper and fluorescent inspection light are provided with height adjustment

- Comply with cGMP standard

With 100% reversible, 100% of the tablets are held in reserve for inspection with inspection capacity about 7-8 lakh tablets per shift depending upon product size and quality.

Operation:

Tablet / caplet to be inspected are fed in hopper. Tablet gets placed automatically on the PVC conveyor through vibrator. The tablet move along with the other face of the tablet is inspected during its motion on the conveyor. Dust extracting tray provided to connect the dust extractor.

Trays provided to collect rejected tablets. 100% perfect tablets fall into the collection container.

Output:

inspection capacity about 7-8 lakh tablets per shift depending upon product size and quality

FULLY AUTOMATIC COATED TABLET / CAPSULE LINEAR PRINTING MACHINE

- Fully Automatic printing machine for capsule/tablet of any size

- 100% feeding gives higher output depending upon the size of capsule/tablet. Smaller the size, higher the output

- Prints on any shape-Round, Oval, Hexagonal, and Triangular etc.-Wax, Sugar or film coated tablets.

- Provides sharp printing on both capsule and tablets

- Imported pneumatic components used for better performance

- Hardened gears and shafts give longer life span

- A versatile, trouble free, easy to operate machine

- Prints on two sides on a vast range of products

- Almost any size and shape like Round, Oval, Football, Pumpkin seed, Coffin, Triangular or Hexagonal tablets, Wax, Sugar and Film coated tablets, soft / Hard gelatin capsules Polished and Sealed compressed products all are handled on Printers.

UTILITIES REQUIRED:

- Minimum air requirement 10 p.s.i to 75 p.s.i. only.

- Edible Ink 45-50 Lakh/Kg. on continual usage

- IPA 20% of Edible Ink for Capsule

- IBA 20% of Edible Ink for Tablet.

- Scrapper Blade - 48 HR Span/ Each. (May break on higher tighten).

- Air Pressure Max. 75 psi.

- Humidity : 40 Deg. - 50 Deg rh.

- Air Condition : Required for sugar coated tablets / Capsules and Soft/Hard Gelatin Capsules.

- Room/Space Required: 9'L x 9'W x 8'H

FULLY AUTOMATIC DOUBLE STAGE CAPSULES INSPECTION CUM POLISHING MACHINE

FEEDING SECTION:

This section consists of stainless Steel Hopper, a Stainless Steel Vibrator and a Stainless Steel Drug Powder Collector. Due to vibration as the capsules pass through the vibrator some amount of drug powder gets collected in the Stainless Steel collector.

INSPECTION SECTION:

This section consists of food grade conveyor belt with variable speed drive and lighting from above to inspect the capsules. The capsules move on the conveyor belt while moving they revolve around the axis due to the angular guides. The defective capsules can be sorted out by the operator through visual inspection. The defective capsules sorted can be removed manually by puckers or by hand.

POLISHING SECTION:

This section consists of two Stainless Steel chambers fitted with a filter cloth; a revolving variable speed spiral nylon brush, stainless steel powder collector and vacuum dust collector. The capsules travel from one end of the brush to the other end. During this travel they are subjected to roll in between the Nylon bristles and sucked by the Dust Collector (Since the capsules are polished twice i.e. in two chambers the powder settled at the edge of the capsules also get removed). The capsules coming out of the chute are thoroughly polished, glossy and clean.

HOT PRONT – 300

| Specifications : | |

| Voltage | AC 220V/50Hz, 110V |

| Power | 180 w |

| Ink Roll Size | 11 x 32 x 36 mm |

| Speed | Upto 300 prints per minute |

| Printing Position | 5 lines & 15 characters per line |

| Machine Dimension | 440 mm x 345 mm x 260 mm |

| Shipping Dimension | 490 mm x 395 mm x 310 mm |

Type Size |

1 mm to 4.5 mm |

| Net Weight | 23 kg |

| Gross Weight | 38 kg |

Features:

Printing options-Brass Types or Rubber Stereos. No ink is used – hence no spoiling of machine and floor area neat. Clean operation Adheres to complete WHO GMP norms about clean room and sterile areas Good adhesion on Laminated & Varnished Labels, Polyester & BOPP Pouches, Aluminum Foil or any other Porous as well as Non-poruous surface Photoelectric mechanism Automatic temperature control Automatic counting of the labels / pouches etc. Adjustable print position – printing at precisely designated space Fast Drying speed – very efficient upto 300 prints per minutes Changeover within seconds Economical; and virtually maintenance free.

FLEXOGRAPHIC PRINTER - FX

Technical data:

- Maximum reel width 300 mm (It is possible to manufacture a machine that can work with larger reels, quotation on demand)

- Maximum reel diameter 250 mm (It is possible to manufacture a machimne that can work with larger reels, quotation on demant)

- Maximum reel weight 30 Kg

- Internal diameter 75 mm

- Speed 30 meters/min

- Weight 175 Kg

- Dimensions 820 x 900 x 950 (h) mm

- Electrical power 0,75 KW

The Flexographic printer FX prints flexible material, bought blank and personalized only when needed and in the required quantity.The machine is user friendly and inexpensive in inks and cliches.

The FX is made with aluminum balcony structure for an easy remonval of the reels, cliches and ink tray. It has a motor with an electronic inverter that allows adjusting and setting the desired working speed. The fine tuning permits a perfect coupling between the printing cliche and the aluminum film. It can run without the continuous presence of an operator.

The printed foil is re-winded by means of servomotor thus granting constancy in tension.

This way the printed foil will be perfectly re- winded and ready for the successive use on the blistering machine. The operator can set the exact film quantity to be printed by touching the screen. The machine will stop once the work is completed.

The machine prints in one color.You can print a second color but without registration, passing the foil one more time.

The FX is very compact and can fit in a small room.It features safety guards, PLS and HMI.

© 2014 Creation. All rights reserved | Design by Sai Web Solution